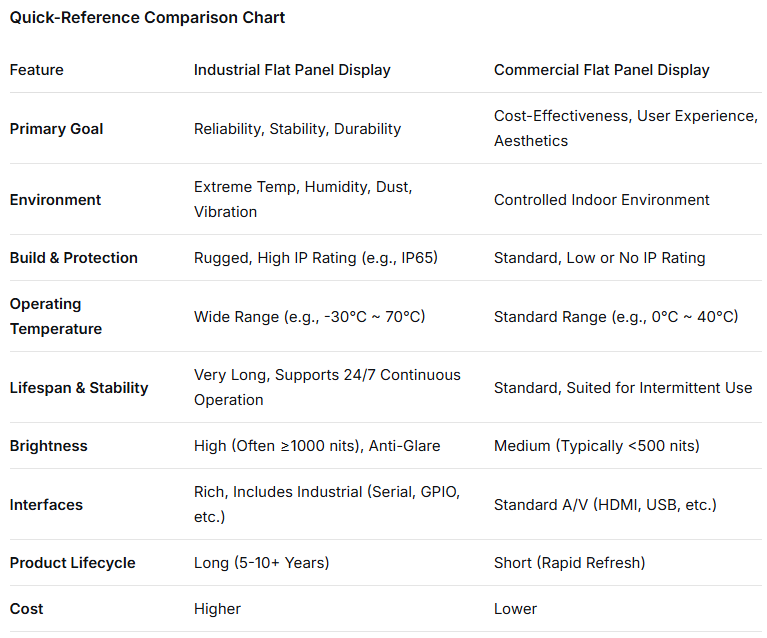

In the realm of digital display devices, industrial flat panel displays and ordinary commercial flat panel displays serve distinctly different application scenarios and requirements, even though they may look similar. Understanding the core differences between them is crucial for selecting the right product for a specific purpose.

1. Design Purpose and Operating Environment

Commercial displays are designed primarily for everyday office use, home entertainment, or retail environments. They typically operate in controlled indoor conditions, focusing on cost-effectiveness, aesthetic design, and user interaction experience (like touch sensitivity and vibrant colors).

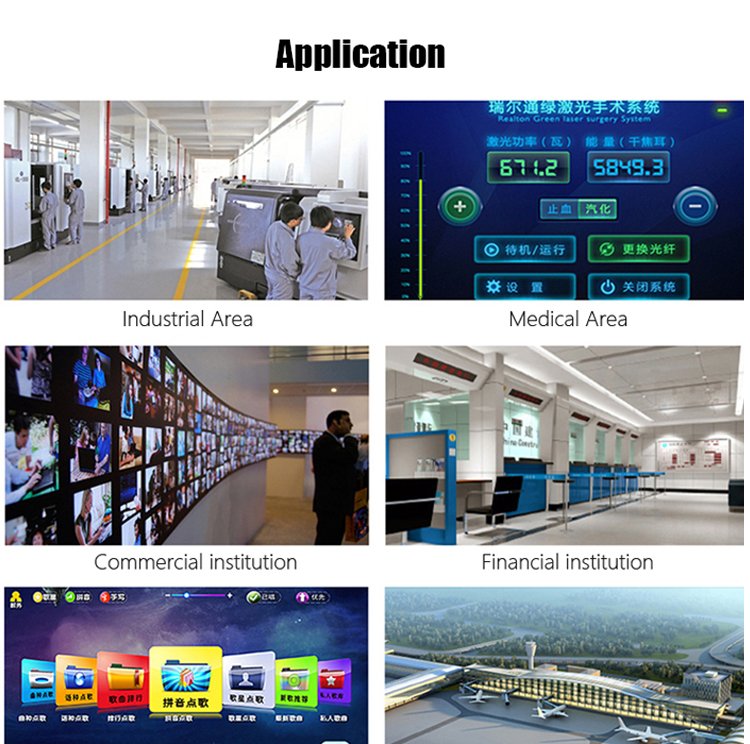

Industrial displays are engineered for harsh environments. They must possess extremely high reliability to withstand extreme temperatures, humidity, dust, oil, vibration, and even corrosive chemicals that may be present in places like factory floors, outdoors, medical facilities, or transportation systems. Consequently, industrial displays usually feature rugged enclosures (often metal) and have higher ingress protection ratings (e.g., IP65/IP67, indicating complete dust and water resistance).

2. Performance Parameters and Reliability

- Durability and Lifespan: Core components of industrial displays (like backlights, capacitive touchscreens) are specially selected and reinforced. Their Mean Time Between Failures (MTBF) is much higher than commercial products. Backlight life often reaches 50,000 to 100,000 hours, far exceeding that of commercial displays.

- Wide Temperature Operation: Industrial displays can operate stably across a very broad temperature range (e.g., -30°C to 70°C), whereas commercial displays are generally designed for standard room temperature (e.g., 0°C to 40°C).

- Stability and Consistency: Industrial applications require displays to run 24/7 without interruption while maintaining consistent performance over time. Commercial displays are not designed for such continuous, high-load operation.

- Brightness and Readability: For outdoor or high-ambient-light environments, industrial displays require very high brightness (typically 1000 nits or more) and anti-glare treatment to ensure clear visibility. Commercial displays usually have lower brightness (250-500 nits).

3. Connectivity and Expandability

Commercial displays offer standardized interfaces (like HDMI, DP, USB) to meet mainstream audio/video and data transfer needs.

Industrial displays provide richer, more specialized interface options (such as GPIO, serial ports RS-232/485, Ethernet ports), facilitating connection to industrial control systems, sensors, or embedded devices. They also frequently support panel mounting, VESA mounts, or customized mounting solutions.

4. Product Lifecycle and Support

The consumer electronics market evolves rapidly, and commercial display models may be discontinued within a year or two. Industrial projects have long lifecycles, so industrial displays typically have product lifecycles of 5-10 years or more, with guaranteed long-term technical support and spare parts availability. This is essential for ensuring the continuous operation of production lines or critical systems.

Conclusion

In short, commercial flat panel displays are “built for experience,” prioritizing value and aesthetics. Industrial flat panel displays are “built for the mission,” pursuing ultimate reliability, durability, and stable performance in adverse conditions. When choosing, for standard indoor applications, commercial displays are cost-effective. For challenging environments or continuous operation requirements, investing in an industrial display is a wise decision to ensure long-term system stability and reduce the cost of downtime.